Hong Kong Main

Board Listing

Stock Code: 2283

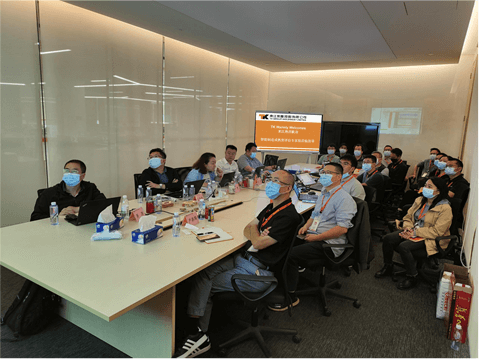

From April 18 to 20, 2022, a panel of five experts from the Intelligent Manufacturing Maturity Assessment team conducted the second phase of formal compliance evaluation at TK Precision in accordance with the "Maturity Model of Intelligent Manufacturing Capability" (GB/T 39116-2020). After three days of rigorous on-site investigation and verification, the expert panel unanimously confirmed that TK Precision meets the Level 3 requirements of the Intelligent Manufacturing Capability Maturity Standard and issued the certificate.

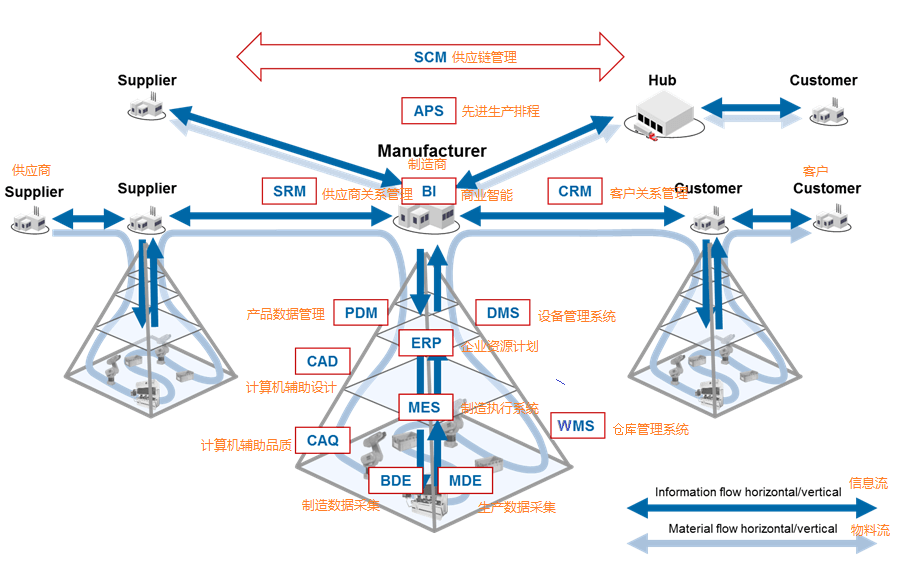

The "Maturity Model of Intelligent Manufacturing Capability" (GB/T 39116-2020) aligns with the national "Made in China 2025" strategic development plan and is a national standard officially released under the leadership of the China Electronics Standardization Institute, providing reference models, assessment elements, evaluation methods, and assessment processes for intelligent manufacturing capability maturity evaluation. The model describes the stepped objectives and evolution path for enterprises implementing intelligent manufacturing, proposing core elements, characteristics, and requirements, comprehensively evaluating enterprises' digital, networked, and intelligent development levels across dimensions including personnel, technology, resources, and manufacturing through five maturity levels from low to high. Level 1 Process Management (Planning Level) requires enterprises to begin planning the foundation and conditions for implementing intelligent manufacturing, capable of process-based management of core business functions (design, production, materials, sales, service). Level 2 Digital Transformation (Standardization Level) requires enterprises to use automation technology and information technology to transform and standardize core equipment and business operations, achieving data sharing within single business functions. Level 3 Network Integration (Integration Level) requires enterprises to integrate equipment and systems to achieve cross-business data sharing. Level 4 Intelligent Production (Optimization Level) requires enterprises to conduct data mining of personnel, resources, and manufacturing to develop knowledge and models, achieving precise prediction and optimization of core business functions. Level 5 Industry Chain Innovation (Leading Level) requires enterprises to continuously drive business optimization and innovation based on models, achieving industry chain collaboration and developing new manufacturing and business models.

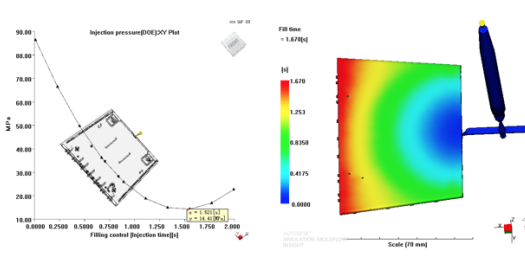

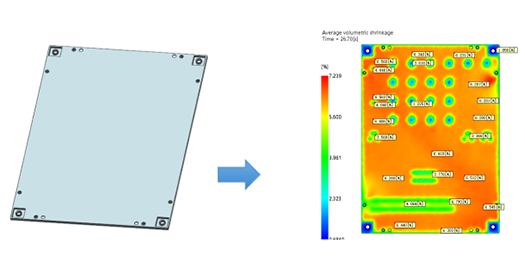

Under TK Group's unified Industry 4.0 strategy deployment, TK Precision has achieved remarkable progress in intelligent manufacturing. Since 2017, the company has continuously increased investment and research in automation and intelligence of production equipment and systems, building and improving information systems, implementing and optimizing existing business processes, and expanding new information management modules including SAP, OA, CAD, BI, MES, PM, WMS, and EAM systems. The company has introduced high-end automated equipment, purchasing over 70 imported four and six-axis industrial robots from FANUC, KUKA, and YAMAHA, creating more than 50 precision automated production lines and production units. This has enhanced production line automation and intelligence levels, elevating product quality and production efficiency to new heights and significantly strengthening TK Precision's core competitiveness.

TK Precision's intelligent manufacturing achievements were unanimously recognized by the five-member expert panel, representing the highest affirmation of its accomplishments in intelligent manufacturing. As of May 2022, 205 enterprises nationwide have received intelligent manufacturing capability compliance ratings: 1 enterprise at Level 1, 131 enterprises at Level 2, 56 enterprises at Level 3, 17 enterprises at Level 4, and none yet at Level 5. TK Precision is the 40th enterprise nationwide to receive Level 3 certification. Other well-known enterprises achieving Level 3 include Sunwoda Intelligent, Hytera Communications, Salcomp Technology, Luxshare Acoustics, Fenda Intelligent, and Wistron. Familiar companies at Level 2 include Mould-Tip, Everwin Precision, Changhong Technology, Ace Mold, Tontec Precision, Merry Electronics, ASH Cloud, Leadeon, and Parkway. Level 4 enterprises include PetroChina, Weichai, Haier, BOE, Foxconn, and Jabil Electronics.

TK Precision's achievement of the Level 3 intelligent manufacturing certificate marks both a milestone in TK Group's Industry 4.0 journey and a new starting point. We need to consider and implement the valuable suggestions provided by the expert panel during the assessment process regarding planning and implementation for higher levels of intelligent manufacturing, further strengthen organizational strategy and talent reserve for intelligent manufacturing, accelerate the construction of an intelligent manufacturing development ecosystem, deeply advance intelligent production and industry chain innovation, and continuously enhance our core competitiveness. Let us continue contributing to TK's Industry 4.0 journey and strive for achieving an even higher intelligent manufacturing maturity rating!