Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

Business Scope

Business Scope

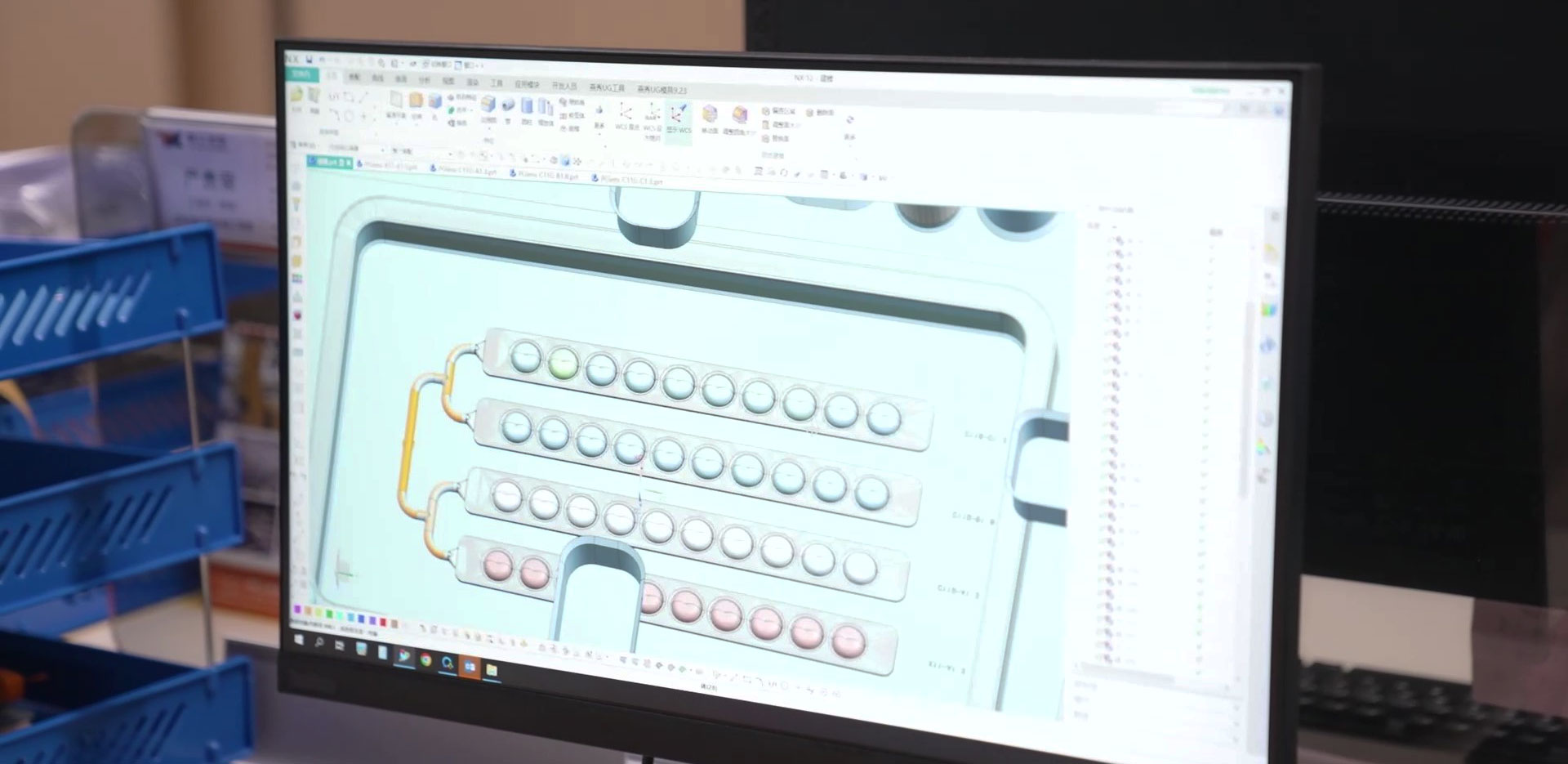

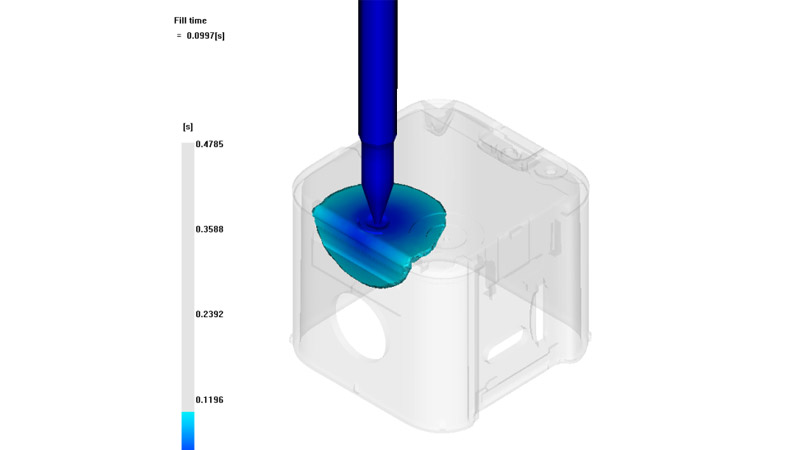

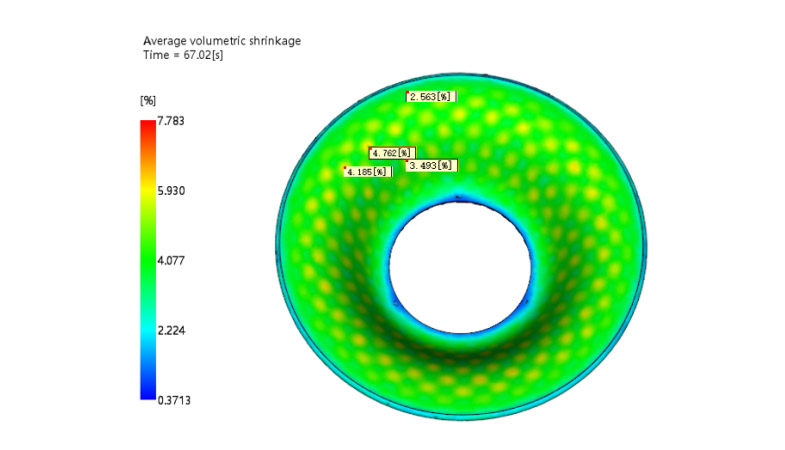

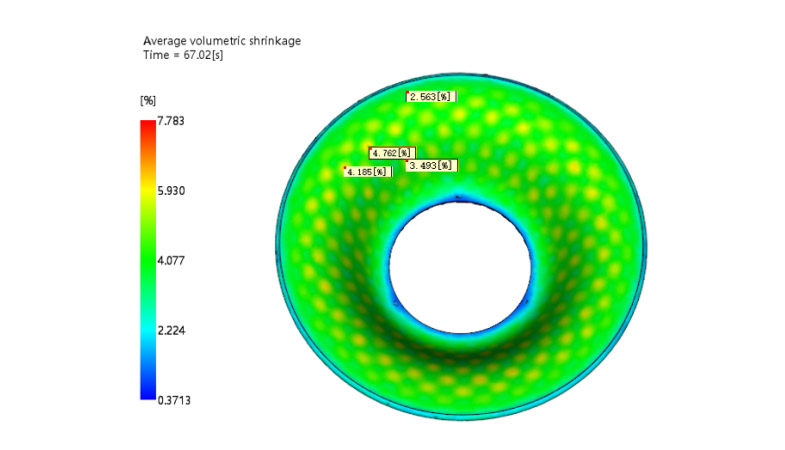

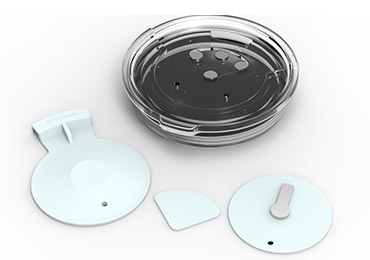

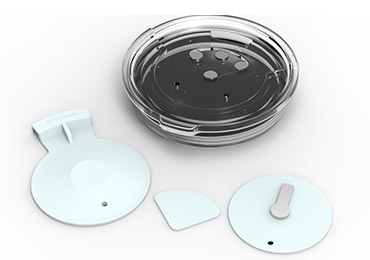

Component Solutions

Component Solutions