Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

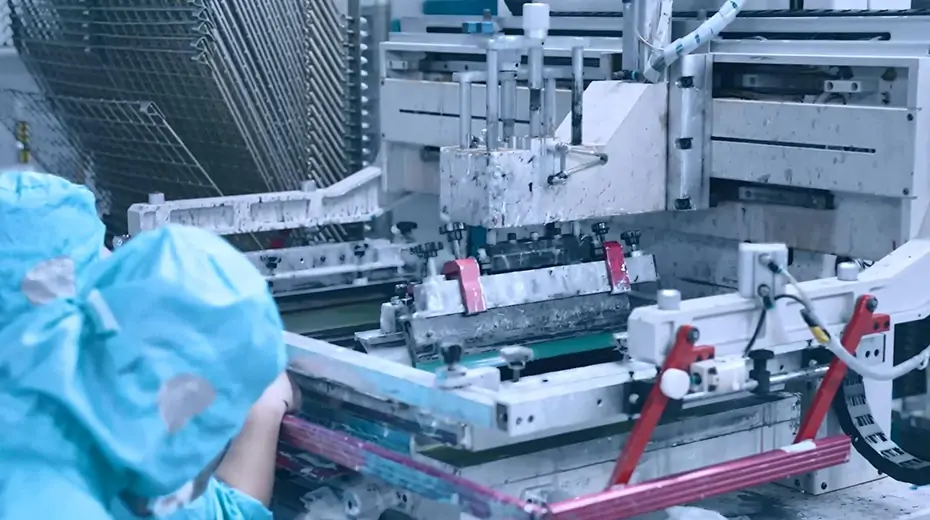

Business Scope

Business Scope

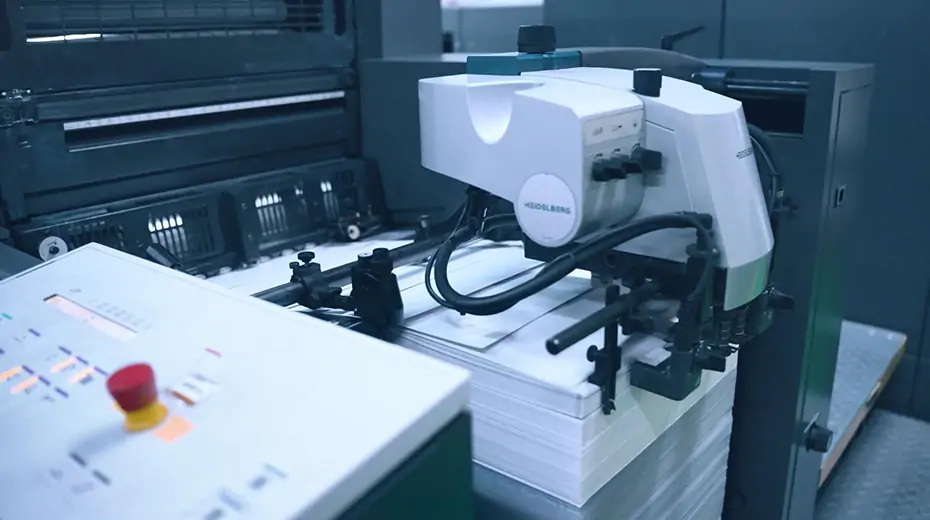

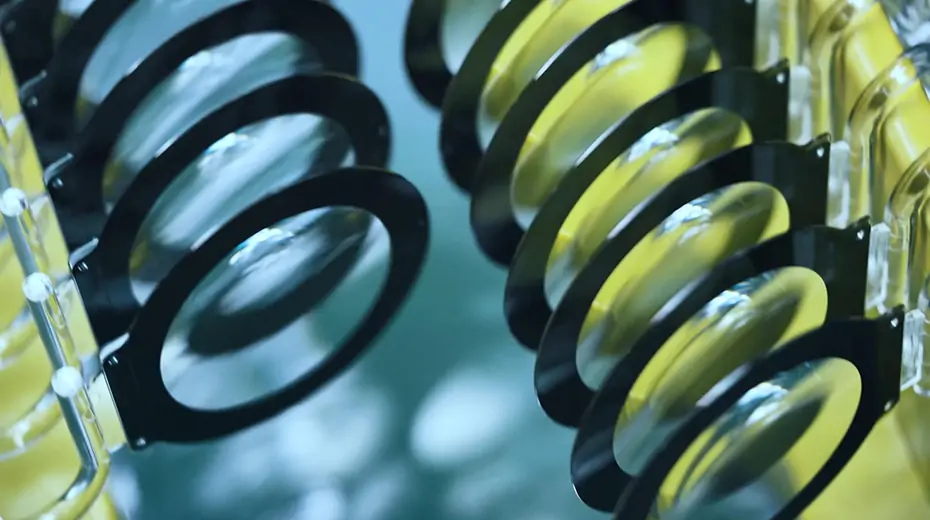

Component Solutions

Component Solutions