Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

Business Scope

Business Scope

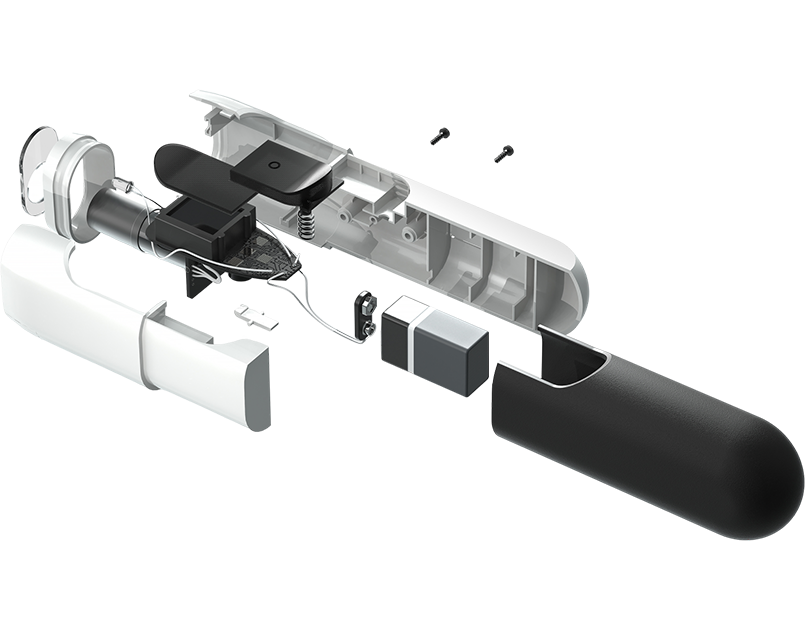

Component Solutions

Component Solutions

These devices require materials that are heat-resistant and chemically resistant, with high demands on material selection and process stability in the injection molding process. Liquid Silicone Injection Molding