Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

Business Scope

Business Scope

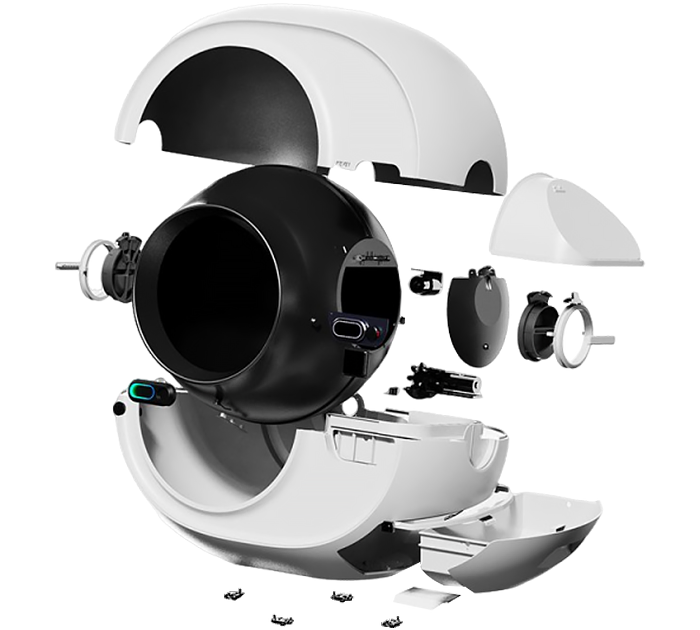

Component Solutions

Component Solutions

Integrating multiple sensors and speakers into a compact form requires advanced injection molding techniques, with high demands for precision and complexity.

The large screen size and slim design pose challenges for the uniformity and strength of the injection molding process.