Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

Business Scope

Business Scope

Component Solutions

Component Solutions

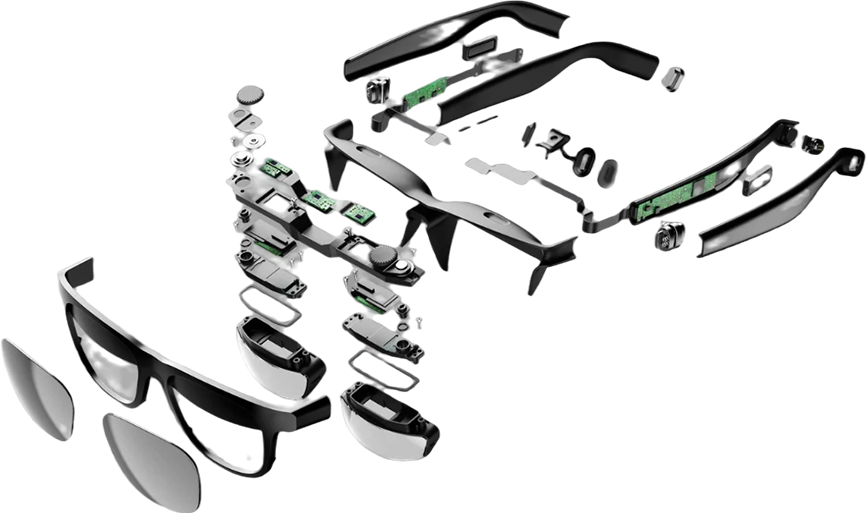

The compact size and complex internal structure present challenges in injection molding accuracy and miniaturization technology.

Require precise ergonomic design, with special emphasis on the elasticity and durability of the materials.

Precision optical components and complex circuit designs require extremely high standards for the injection molding process.

The precise coordination of multiple buttons and joysticks demands high precision in the injection molding molds.