Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

Business Scope

Business Scope

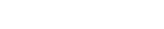

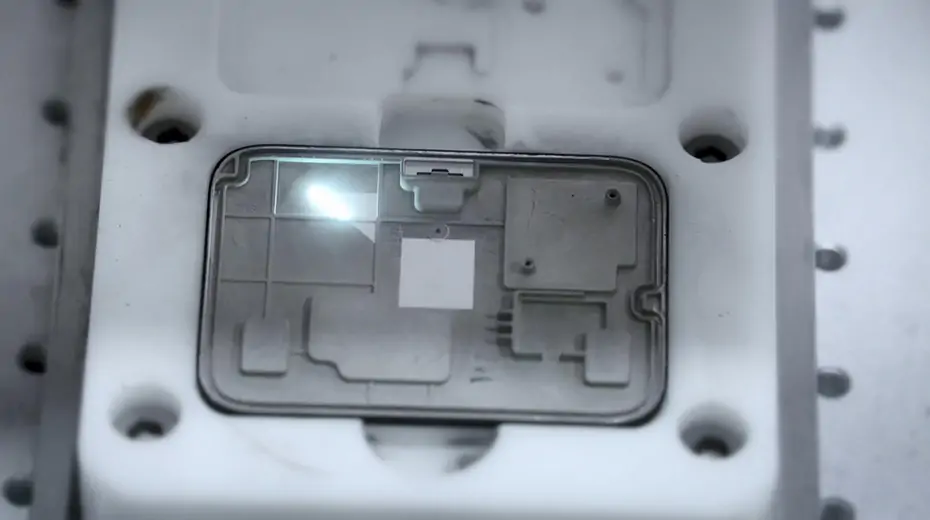

Component Solutions

Component Solutions

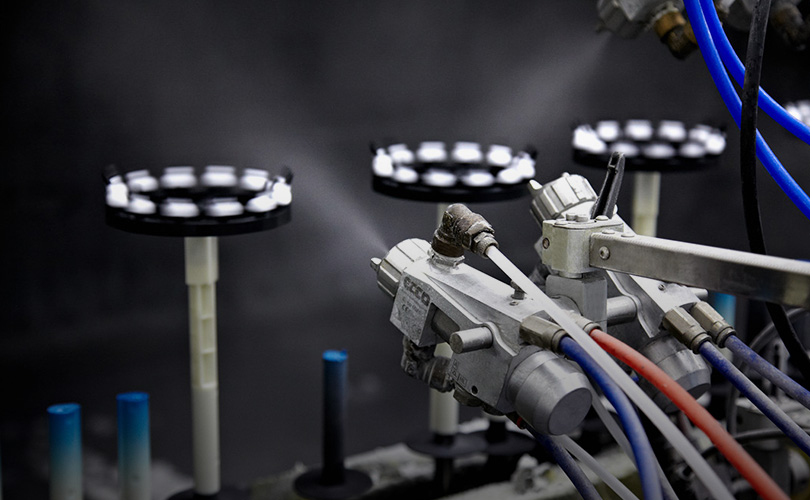

3 Spray Stations and 3 Curing Station

100,000-Class Cleanroom

10,000-Class Clean Spray Booth

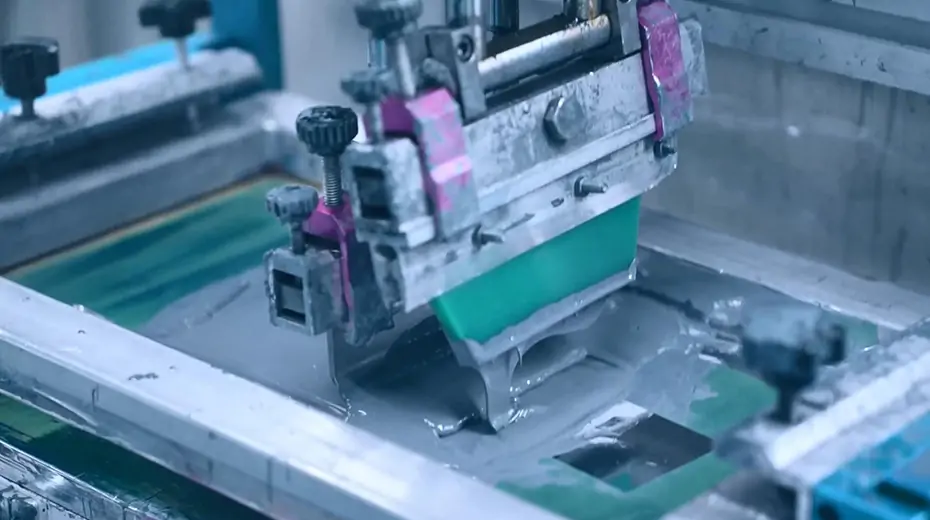

UV Coating

PU Paint

Soft Touch Coating

High-Gloss Coating

Electromagnetic Shielding