Hong Kong Main

Board Listing

Stock Code: 2283

Hong Kong Main

Board Listing

Stock Code: 2283

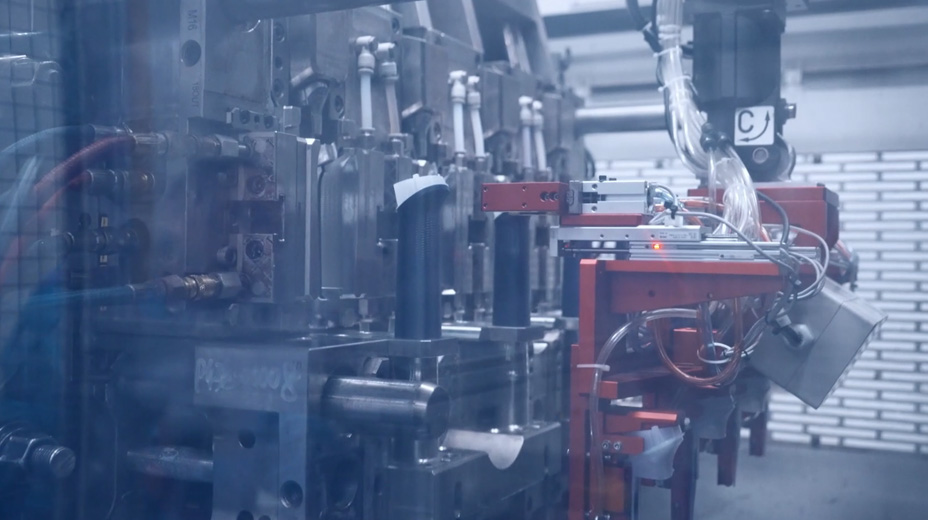

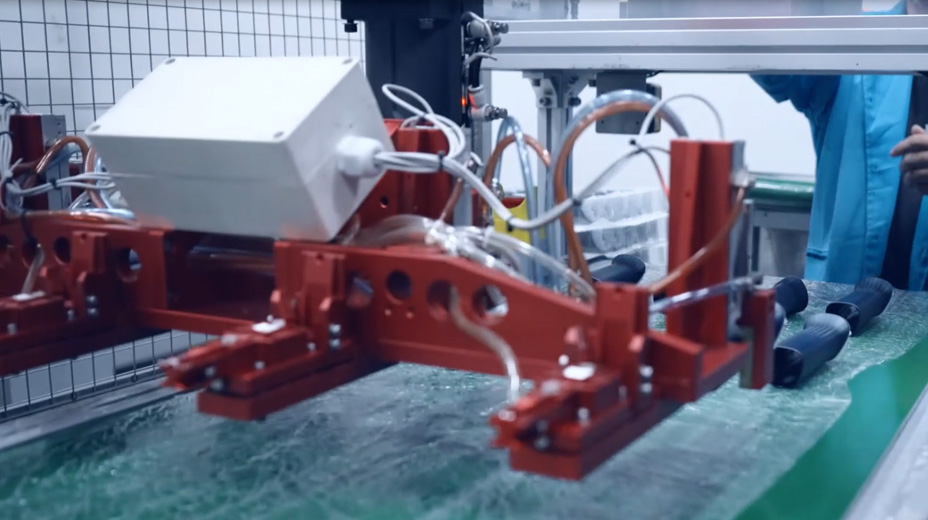

Business Scope

Business Scope

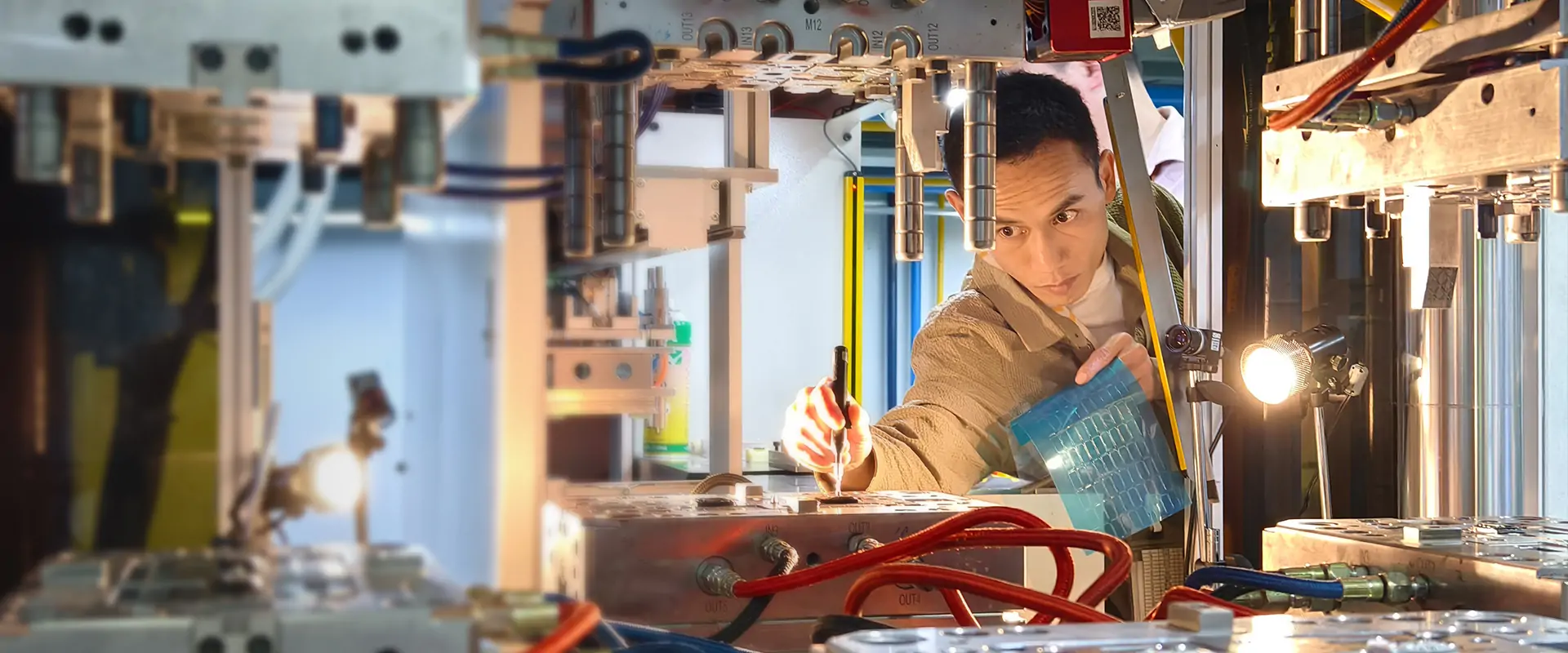

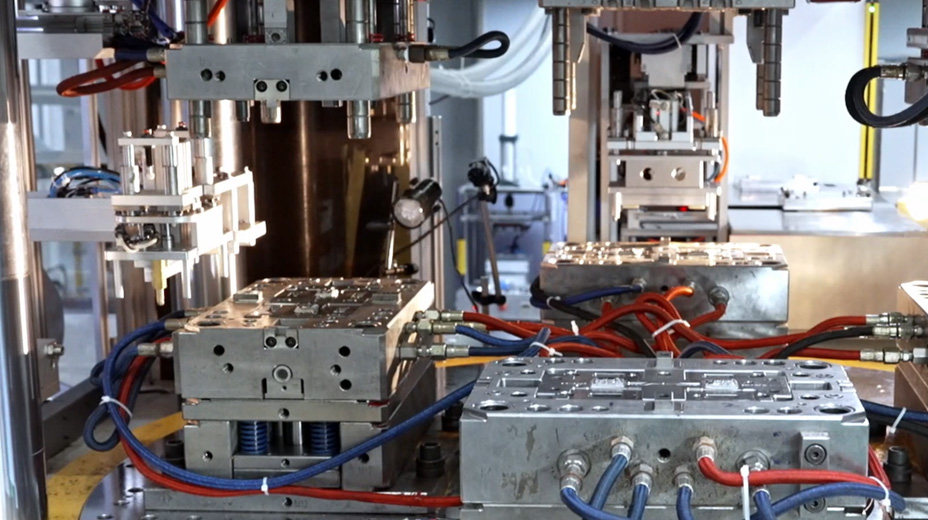

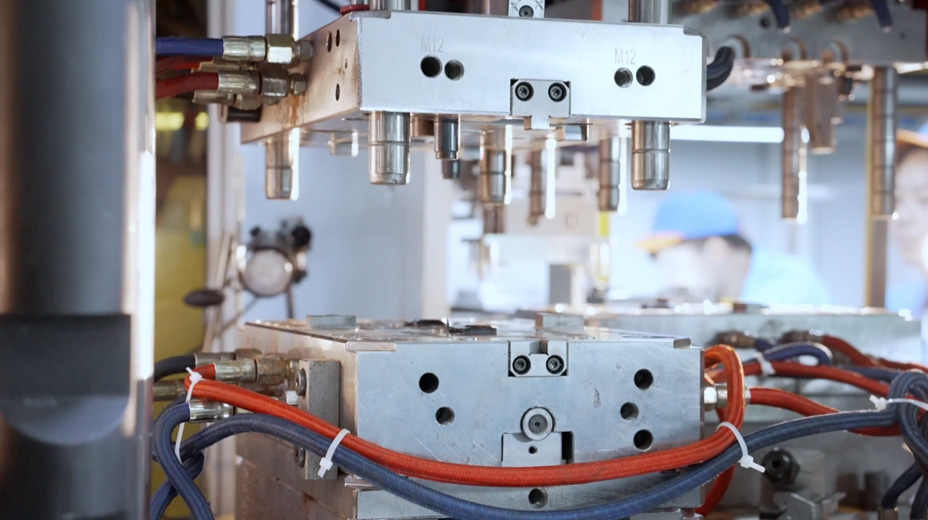

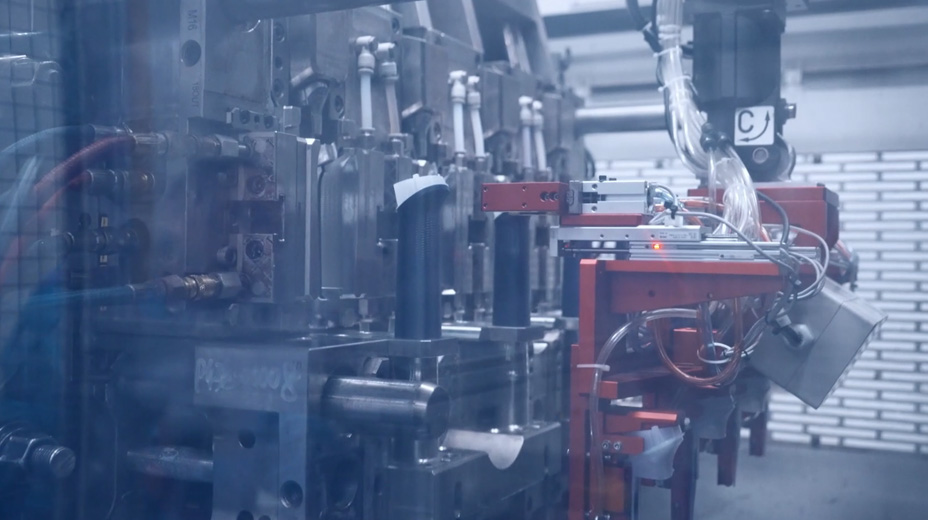

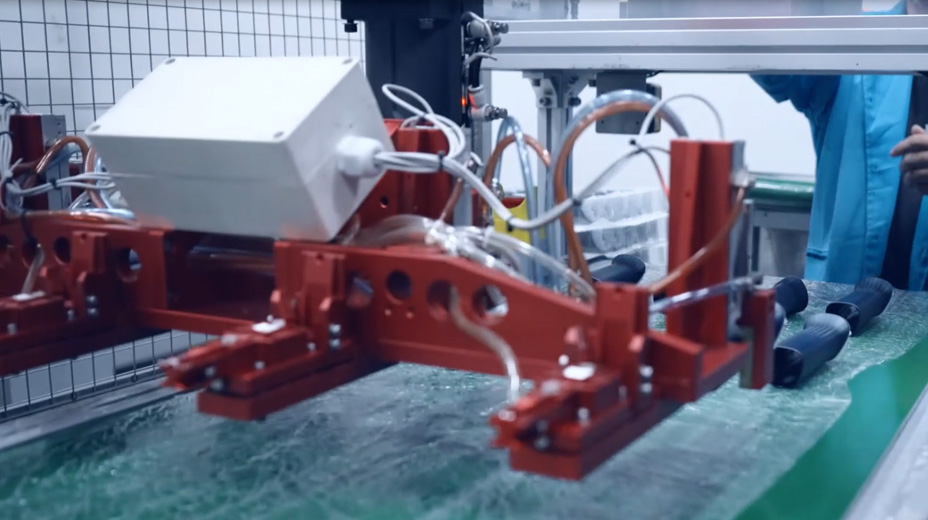

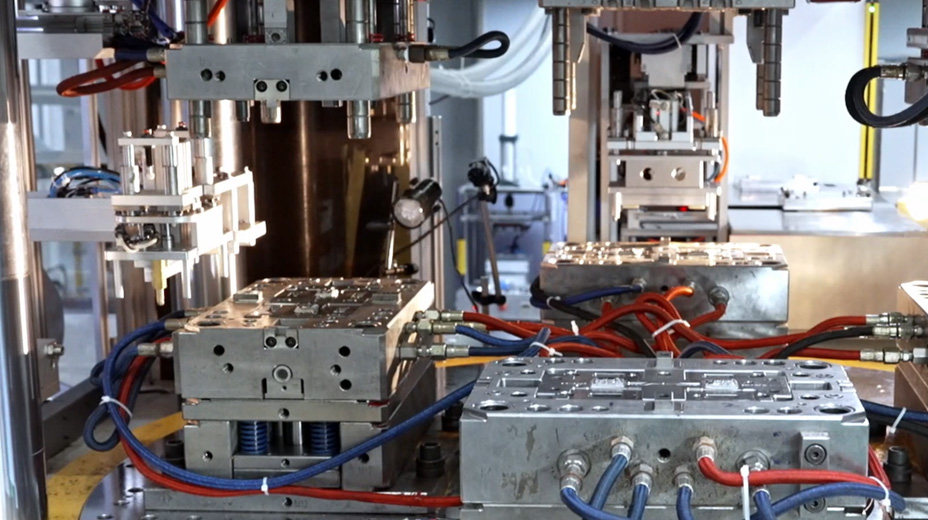

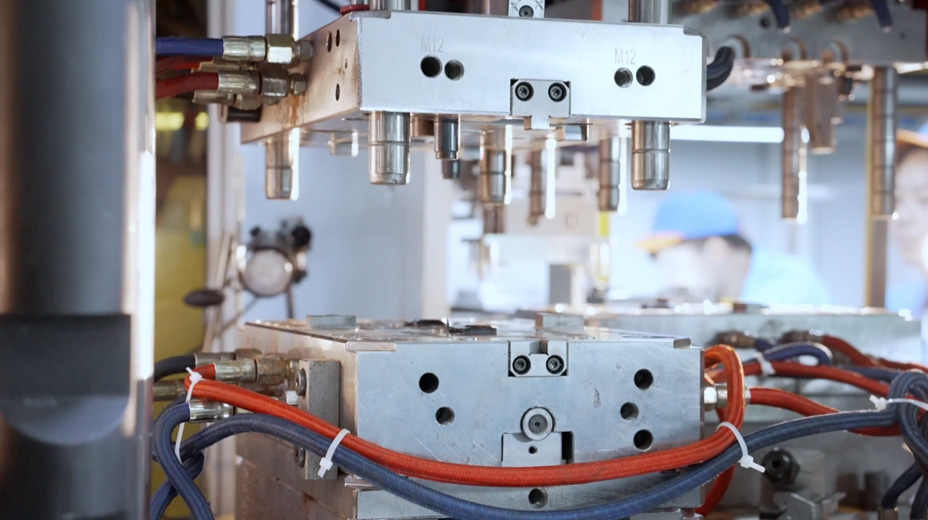

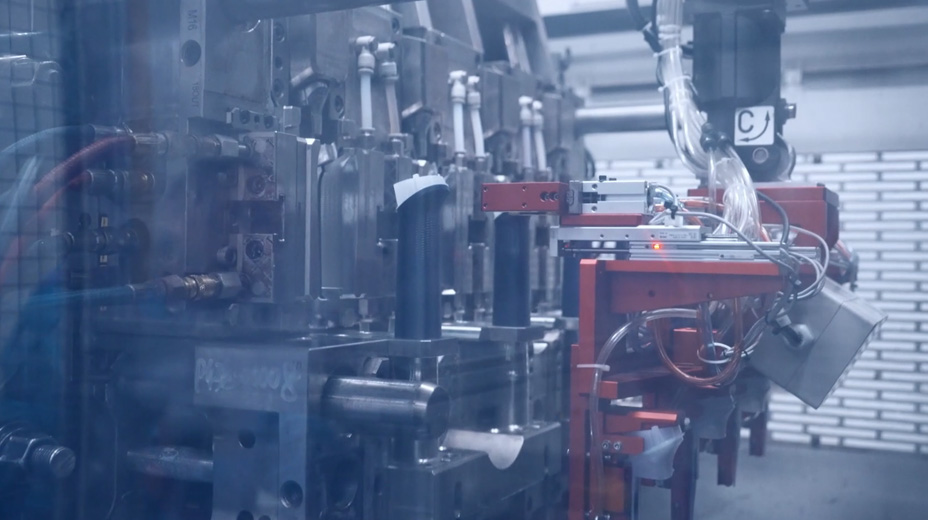

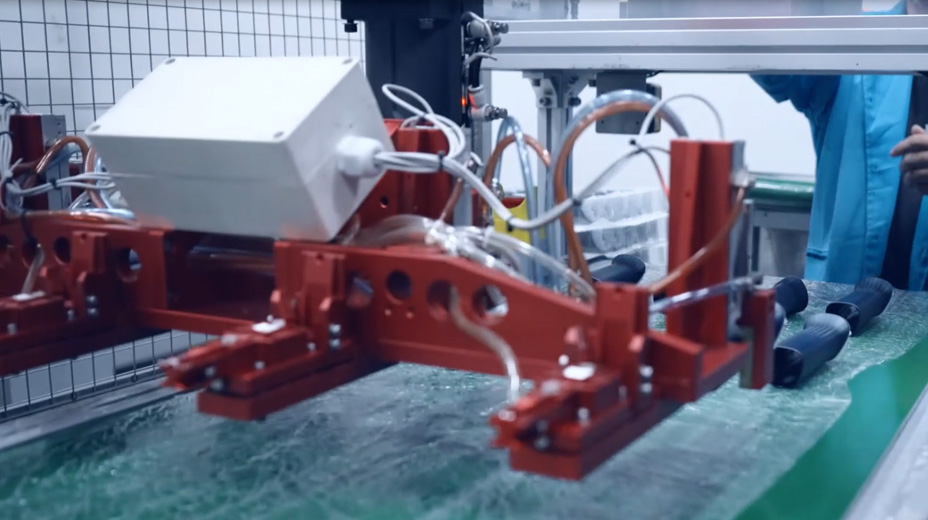

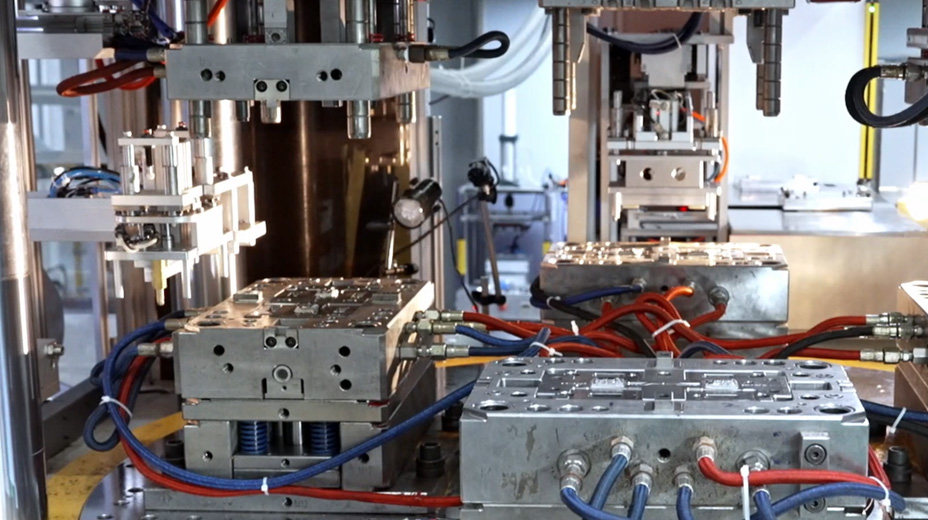

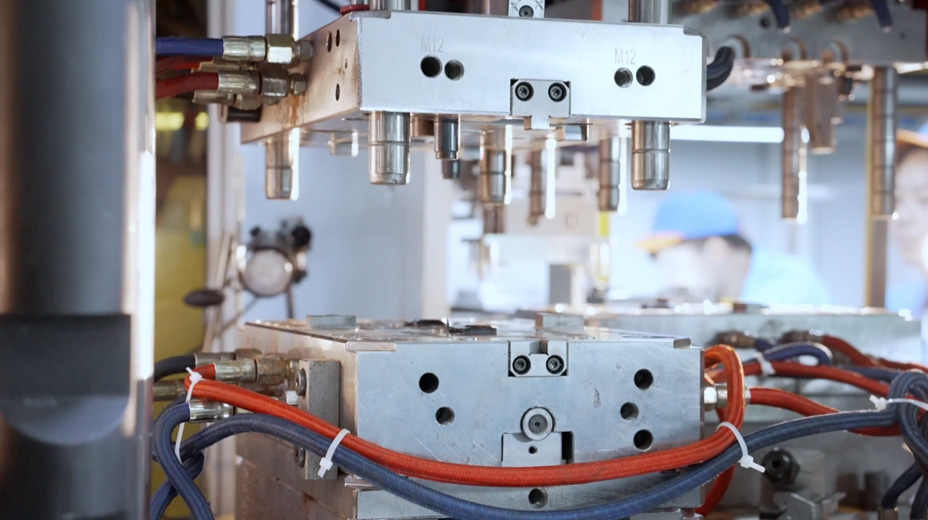

Component Solutions

Component Solutions